Paper Schmidt PS8000

Home / Products / Roll Hardness Measuring / Paper Schmidt PS8000

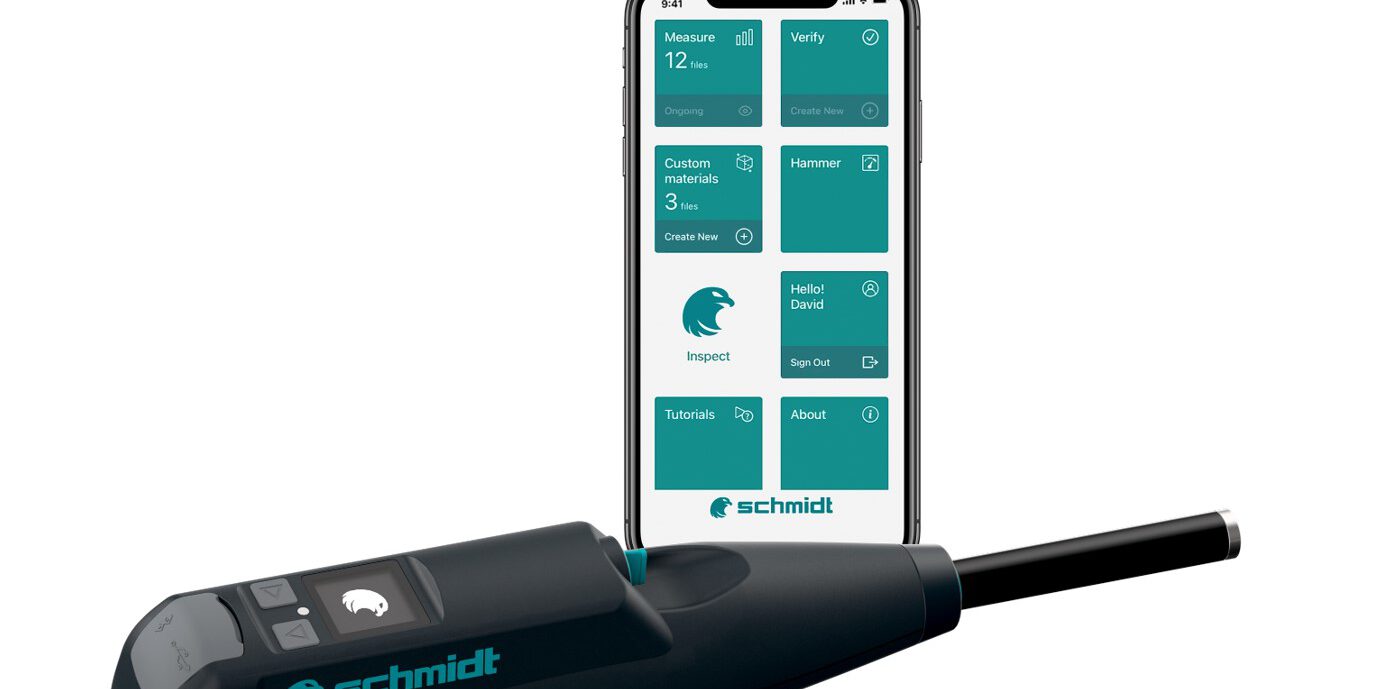

Proceq Paper Schmidt PS8000 – the newest edition of the legendary SchmidtHammer LR

Category: Roll Hardness Measuring, Paper, Cellulose, Carton

Manufacturer: Proceq

Proceq Paper Schmidt (successor to Schmidt Hammer LR) | The first rebound hammer to test the winding hardness for all materials on a roll (paper roll, etc.). Robust & incredibly accurate!

Usage:

Hardness testers for all kinds of web goods (rolls or sheets): Foil and paper rolls (large, medium and small paper rolls) / leather / coated rolls / lottery tickets / handkerchiefs

Versions:

Can be ordered as standard or optionally with Bluetooth thermal printer.

What distinguishes the new SchmidtHammer?

The Paper Schmidt is the first rebound hammer that is used specifically to test the winding hardness of film and paper rolls. A new measuring principle and an extremely flexible firing pin enable previously unachieved accuracy and repeatability when determining the roll profile. The robust design of the Paper Schmidt ensures a longer service life of the device under the difficult operating conditions in the paper industry.

Special functions such as predefined tolerances simplify the interpretation of the measurement results significantly.

Particularities:

- The device has an extremely flexible firing pin and works according to a revolutionary measuring principle that is independent of the angle of impact. This makes the Paper Schmidt the leading device in its class when it comes to testing roll profiles.

- The paper roll profile is immediately shown on the integrated display.

- The user interface is extremely intuitive and at the same time language-independent.

- The device automatically calculates the average hardness of the paper roll, the span and the standard deviation.

- In addition, maximum and minimum values can be set in PaperSchmidt. Exceeding or falling below these preset values is displayed immediately.

- The PaperSchmidt is characterized by a high-quality, robust design. A sealing system and specially treated firing pins increase the life of the device significantly compared to other rebound hammers. At the same time, this reduces maintenance costs in industries where the device is used intensively.

- The device is easy to program for individual user requirements.

Scope of application:

- paper industry

- Foils, foils and other plastic webs

Applied standards

TAPPI T 834

Mobile App:

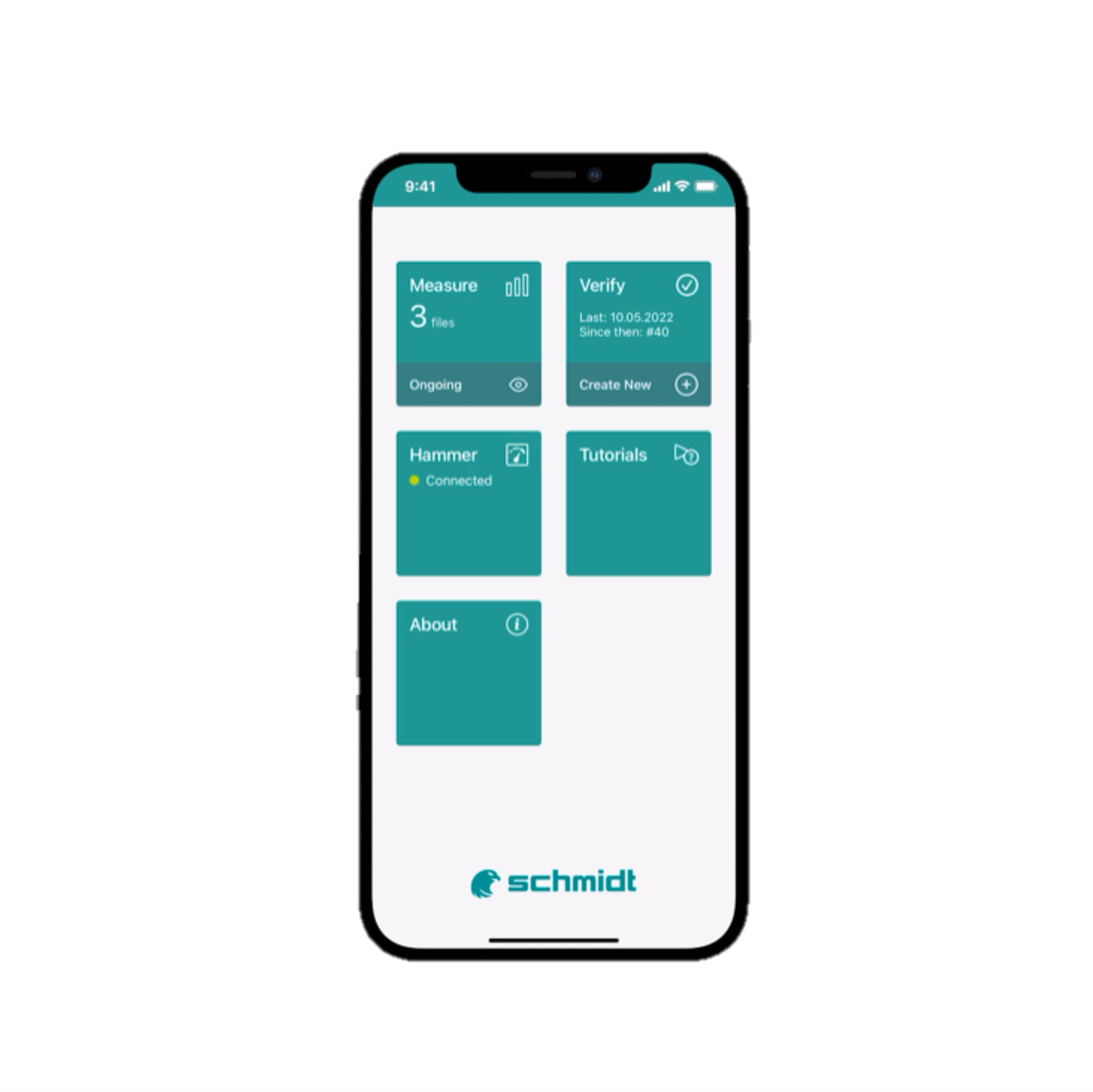

Proceq Paper Schmidt App

App Display:

Any compatible Apple® iOS device (iOS 12

and later)

App Workflow Features

- Voice read-out of each impact (only on iOS®)

- Logbook with geolocation, audio, image and text annotations

- Series statistics

- Generate roll profiles

- ID Barcode and QR code scanner

- Set min/max values

- Single series reporting: CSV

App Verification Features

Software-assisted verification on an anvil

PC Software

Paperlink 2 software runs on Windows 7 or newer

PC Workflow features

- Download and manage roll data

- Instant view on measurement data span

- Set up and change min/max limits

- Display statistics

- Insert measurement comments

- Export data to CSV file

- Export PNG images

Measurement

Roll profile measurement (series of rebound value)

Technology

Optical Rebound Velocity Quotient

Key Features

Impact angle independent

Displays the impacts on-screen as you work

Set min/max values

Connect to PC, mobile app and portable printer

Impact Energy

0.735 Nm

Memory

Instrument memory > 20’000 impacts

Display

Analog & backlit digital (100 x 100 pixels,

graphic)

Connectivity

Bluetooth® LE, USB for charging, updates

and wired data transfer to PC

Standards compliance

TAPPI T834

TAPPI TIP 1004-01

Present