Our technicians have many years of experience with non-contact UBM measuring systems of the laser focus, microfocus, telefocus and UBR20x series. For the calibration we proceed according to the specifications of the former manufacturer. After carrying out the check and calibration, you will receive a calibration certificate with standard connection. Furthermore, we can offer help with hardware and software problems.

Many assemblies of the equipment are repairable or can be replaced. We have different components in stock for replacement. This includes engine control components, sensor controllers, and UBM-compatible PCs. The actual sensors (microfocus, telefocus) can only be repaired for certain defects. Ask, we examine the case of damage.

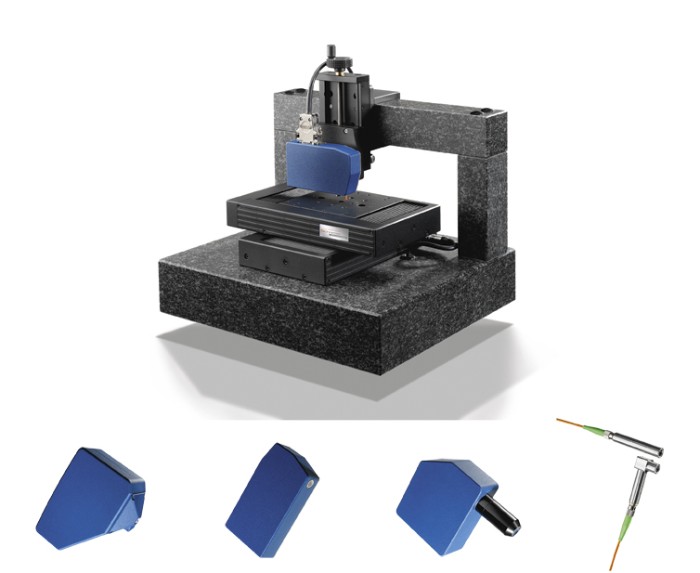

In the event of a sensor failure, the sensors of the AF16, KF3, KF3 / Tele and C1 series can be integrated into your system with significantly better performance. You will receive a driver dll next to the sensor. After installing the sensor, you can continue working in the familiar software environment. The mechanical work varies depending on the system and the sensor, on request we take over the adaptation.

We continue to offer a complete conversion service for your system. All obsolete components are replaced by current products. The package includes a current PC, the Windows® 7-compatible 32bit Inspector software, a new engine control, and a sensor of your choice. Camera components can be partially taken over. The motor and sensor control is housed in two desktop enclosures, no PC plug-in cards are required. After a conversion, your system with a new system of the type Hyperion almost identical in construction. The savings compared to a new system are up to 60% for large measuring systems.